Ref. No.:

1339-09281100

Machine Details:

Technical Details:

-

Control:

-

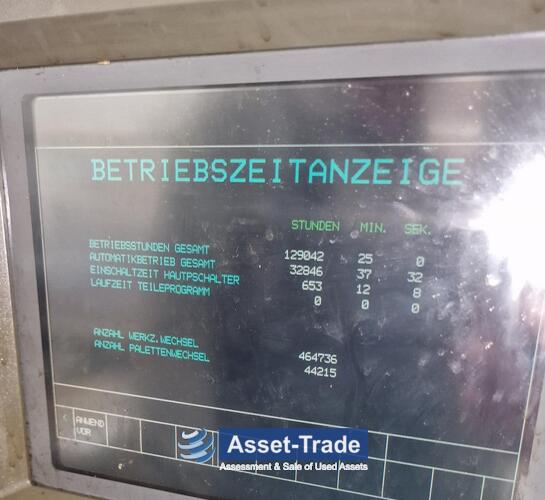

Machine Hours:129.042 hrs.

-

Spindle Hours:700 hrs.

-

Spindle Speed:6.000 rpm

-

Tool Holder:

-

Tool Capacity:80 x

-

X-Axis:2.300 mm

-

Y-Axis:1.400mm

-

Z-Axis:1.525 mm

Travels:

Description:

Description

Used STARRAG HECKERT CWK 1600 H Horizontal machining center

Control Fanuc 16 M

Total operating hours 129.000 std.

Spindle hours since new bearing 700 std.

Technical data:

- Travels

- X - path: 2.300 mm

- Y - travel: 1.400 mm

- Z - travel: 1.525 / 1840 mm

- B - axis: 360 x 0,001 °

- rapid traverse X/Y/Z: 24,00 m/min

- feed rate B - axis: 8,00 rpm

- pallet size: 1.600 x 1.250 mm

- table load: 5,00 tons

- interference circle diameter: 2.200 mm

- spindle speed: 20 - 6.000 rpm

- torque at the spindle: 820 Nm

- drive power - workpiece drive: 28,00 kW

- IKZ - pressure stages: 50 bar

- tool holder: BT50

- tool magazine: 80x

- tool diameter: 280 mm

- tool diameter with 2 free places: 500 mm

- Chip to chip time: 12,00 sec.

- Pallet change time: 52,00 sec

- total power requirement: 80,00 kW

- machine weight: approx. 29,00 t

- Space requirement: approx. 11.00 x 7.00 x H4.50 m

- Incl fog extraction, however, this is defective

STARRAG HECKERT CWK machining centers have proven themselves in the market in countless applications as versatile machining centers that offer high flexibility, efficiency and precision. They are suitable for complex processing of complex workpieces made of steel, cast or light metal. Combining compelling know-how and many innovative ideas, they meet market demands to reduce production and floor time. They constantly aim to reduce non-productive idle and setup times. Large machining centers are ideal for fast, cost-effective and complete machining of large and heavy parts (turning diameter up to 2200 mm, maximum weight 5000 kg). The modular structure offers maximum flexibility and enables the creation of customized manufacturing solutions. The center deals with high-precision, process-optimized and energy-saving processing of housings and prismatic parts, mainly in the agricultural machinery and automotive industry, equipment manufacturing, pump and compressor manufacturing, and the wind energy sector.