Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:4.500 rpm

-

Tool Holder:

-

Tool Capacity:110 x

-

X-Axis:1.600 mm

-

Y-Axis:1.000mm

-

Z-Axis:1.000 mm

Description:

Used DÖRRIES SCHARMANN Solon 3 - CNC machining center with 7 pallets

The Dörries Scharmann Solon 3 CNC machining center offers outstanding high precision for machining complex workpieces. With a Siemens 840D control and a 7-pallet system, it optimizes production through quick pallet changes and significantly reduces idle times. Its CNC machining enables precise travel paths and a high spindle speed of up to 4500 rpm. This machine is ideal for companies that want to machine large workpieces with high efficiency and accuracy. Benefit from a reliable, high-performance solution for your production processes.

2007 Complete modernization to Siemens 840D control

Technical data Solon 3 BAZ:

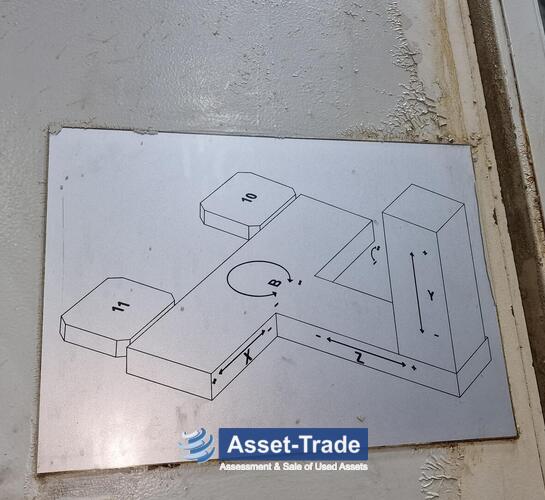

- Travel paths:

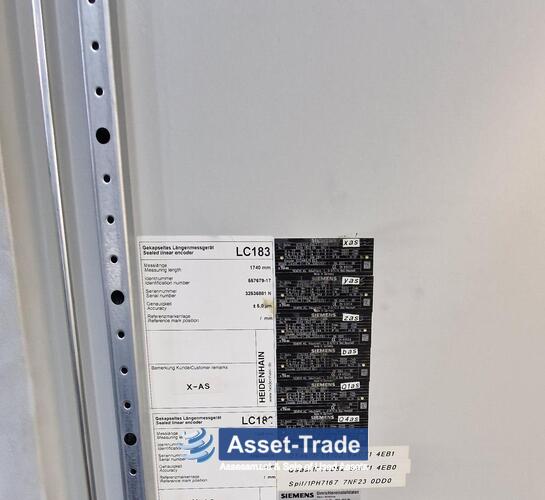

- X-axis from 800 to +800 = 1600 mm

- Y-axis from +50 to +1050 = 1000 mm

- Z-axis from +250 to +1290 = 1000 mm

- Rapid traverse 25 m/min

- Number of tools: 110

- Automatic pallet changing system

- Tooling:

- Number of tools: 110x

- Tool change possible while the machine is running

- Tool management system (TIS) = Automatic tool change system

- Tool change time 8 seconds

- Length/breakage control - Renishaw probe for all types of measuring programs possible

- Spindle with 3 gear levels:

- Level 1: 0 - 532 rpm

- Level 2: 532 - 1600 rpm

- Level 3: 1603 - 4500 rpm

- Spindle power: 37kW

- Spindle mount: SK50 taper

- Efficiency 95%

- Cooling water pressure through the spindle: 30 bar

Technical data HBC:

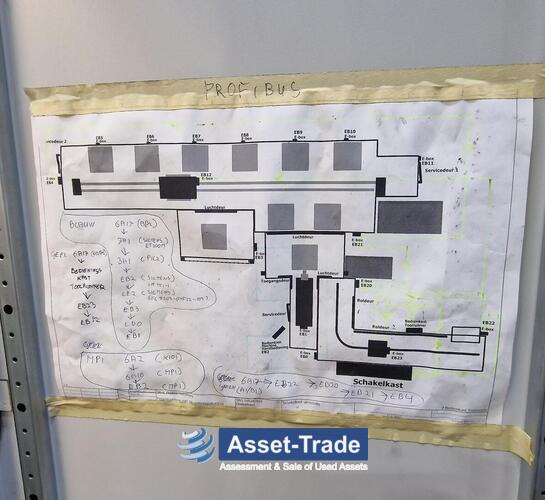

Control version: 850 M

- Table pallets:

- Number of pallets: 7 - STS. Linear pallet transport system

- Table dimensions: 1.000mm x 800 mm

- equipped with 7 T-slots 18 x 30 mm deep 30 mm

- Max workpiece weight on the table: 2500 kg

- Rotary table in the machine

- Maximum width :

- Product is 1600 mm (because of the shower nozzles in the machine)

- and 1075 from front to back

- Front max 150 mm above table

- Back 125 mm above table (because of the big door)

- Front max 190 above table, but then the big Door must be open when moving in and out, otherwise the door will hit the product when moving out and the product will go through the windows when it is at station

- Max. height of product that can go into the machine because of the large door = 1300 mm (measured from the table)

- Oil tanks outside the machine so they can be filled without interruption

- Fixed loading station so we don't have to lug clamping devices back and forth Closed machining cabin, because of smoke and flying cooling water Tool magazine change when machine is rotating

Tools can be purchased separately!!!

Machine can be viewed under power.

The DÖRRIES SCHARMANN Solon 3 machining centre is a high-performance machining centre that can process large and complex products with precision and efficiency. It has a Siemens 840D control system and a rotary table with seven 1000 x 800 mm tables. The machine has three traversing axes: X-axis of 1600 mm, Y-axis of 1000 mm and Z-axis of 1000 mm. The machine can reach a maximum spindle speed of 4500 rpm and a cooling water pressure of 30 bar. The machine has a tool magazine with 110 tools and a Renishaw probe for length and breakage control. The machine also has oil tanks outside the machine, a fixed loading station and an enclosed machining cabin. The DÖRRIES SCHARMANN Solon 3 machining centre is ideal for machining long products with high accuracy and quality. The 7-pallet station is one of the features that make the DÖRRIES SCHARMANN Solon 3 machining centre an excellent machining centre for large and complex products. The machine can switch between different pallets without interrupting the machining process, which reduces non-productive time and increases productivity.