Ref. No.:

143-10251412

Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:4.000 rpm

-

Tool Capacity:24 x

-

X-Axis:630 mm

-

Y-Axis:500mm

-

Z-Axis:550 mm

Travels:

Description:

Description

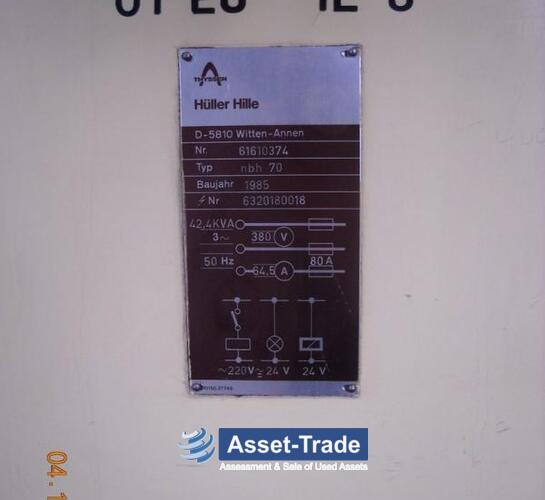

Used HUELLER HILLE NB - H 70 Horizontal Machining Center

|

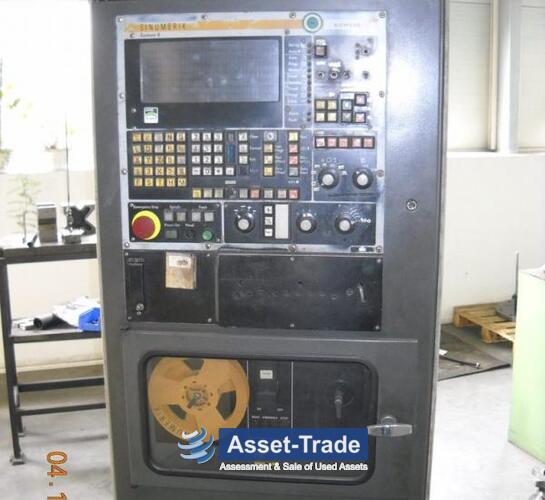

Siemens Sinumerik Sprint 8M control Workspace

Distance in the X-axis

Work spindle

Movable round table / pallet

Feed

Rapid traverse

|

Tool magazine

Druckluftanglage

Coolant system

Times

Accuracies

Electrical equipment

Weight

|

Maschine was in production one month ago. Suggested Repair :check on bearing, main spindle, and belt for main spindle