This great MIKRON - MSM400U LP 5 Axis is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Universal Machine Centres machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

-

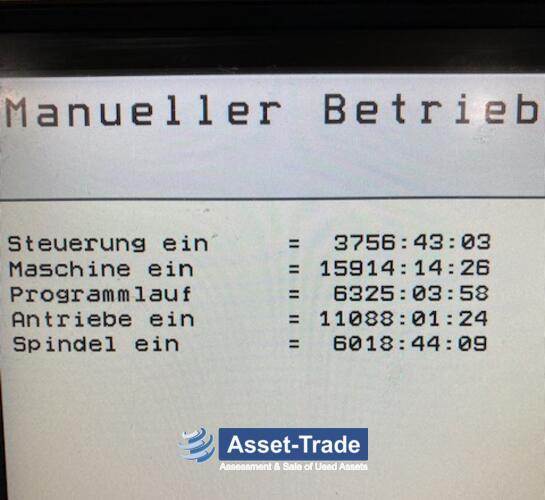

Machine Hours:15.914 hrs.

-

Spindle Hours:6.370 hrs.

-

Spindle Speed:42.000 rpm

-

Tool Holder:

-

Tool Capacity:68 x

-

X-Axis:500 mm

-

Y-Axis:450mm

-

Z-Axis:360 mm

Description:

This great MIKRON - MSM400U LP 5 Axis is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Universal Machine Centres machinery, or Contact us for further help.

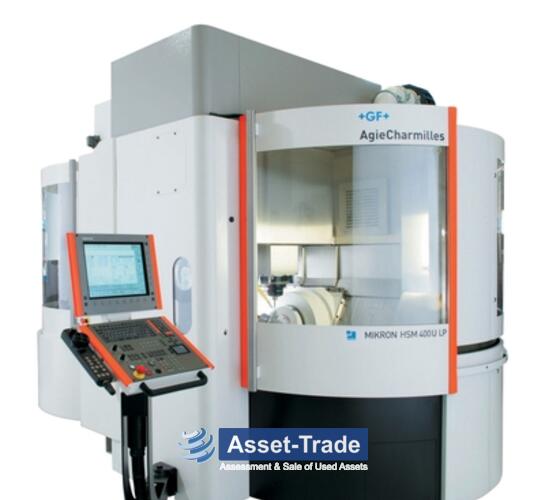

Used GF MIKRON HSM 400 U LP -5 axis high speed machining center

Operating hours machine 15.914 / spindle 6.370 std.

CNC control Heidenhain iTNC 530

Technical data:

- Tool spindle Cool-Core 42.000 1/min - 13.5kW

- Tool magazine 68x Positions HSK E-40

- 5 axes with linear motors

- IKZ 70 bar

- Pallet magazine: 18x Positions

- Round tilting table with chuck

- Pallet Type: 3R-Macro Ø156

- Number of Axes: 5

- An infrared probe from M&H (Hexagon) is installed

- The machine has a camera system installed for tool measurement (ITM)

Travels:

- Max Feed Rapid Rate 40m/min

- X1 Std. 15.748 in. 2,358 ipm

- Y1 Std. 9.440 in. 2,358 ipm

- Z1 Std. 13.779 in. 2,358 ipm

- B1 Std. 220.000 deg25 rpm 25 rpm

- C1 Direct Drive Std. 360.000 deg25 rpm 25 rpm

-

Machine Dimensions (l x w x h)(in.)153 x 124 x 103

The HSM400U LP uses a gantry-style or fixed portal design. The moving parts are mounted on highly stiff, frictionless linear-roller-guide ways. This provides a highly durable and stick-slip-free motion for all running conditions. The machine tables are made of a well ribbed cast iron construction in which all transmission elements like supporting surfaces for guide carriage and the linear drive are integrated.

For the MIKRON HSM 400U LP there is a choice between different pallet-chuck systems. Those chucks are integrated in the table construction.

A weight optimized cast slide has been developed for the z-axis in order to enable a high cutting capacity when machining. Due to the box-form and good ribbing the spindle slide grants highest machine accuracy. The rotary tilt table has been developed by Mikron using optimized direct drive motors for the B and C axes. As a result true 5-axis simultaneous high-speed machining is granted.

This design minimizes the total floor space required by the machine and is particularly suited for production of high value components such as molds, electrodes and production parts, in particular, 3-D complex parts.

The portal and the base of the machine are made of polymer concrete. This composite offers excellent vibration damping characteristics - approximately 10 times greater than cast iron and significantly better than a welded construction, and is significantly more thermally stable then cast iron.. A high degree of damping is essential when working with high feed rates, high acceleration, and requirements for superior surface finishes.