This great HELLER - MC 600 4 axis with pallet pool is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Horizontal Machine Center machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

-

Machine Hours:60.836 hrs.

-

Spindle Speed:6.000 rpm

-

Tool Holder:

-

Tool Capacity:320 x

-

X-Axis:1.700 mm

-

Y-Axis:1.400mm

-

Z-Axis:1.250 mm

Description:

This great HELLER - MC 600 4 axis with pallet pool is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Horizontal Machine Center machinery, or Contact us for further help.

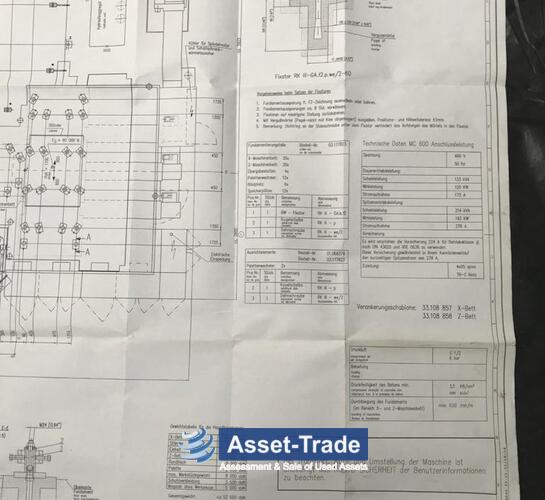

Used HELLER MC 600 4-axis universal milling machine with 6-fold pallet pool

CNC Control Siemen Sinumerik 840 D

Overating Hrs. 60836 ( from October)

Technical data:

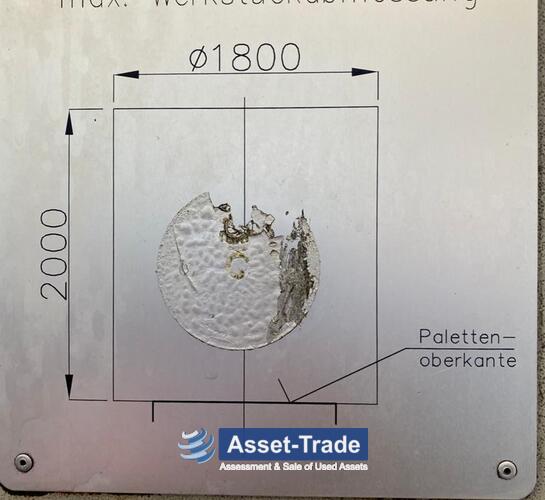

- Travels

- X-axis: 1700 mm

- Y-axis: 1400 mm

- Z-axis: 1250 mm

- B-axis: 360.00 x 0.001 ° Max speed 6 rpm

- Feed forces: 15000N

- Feed rate: 60 m

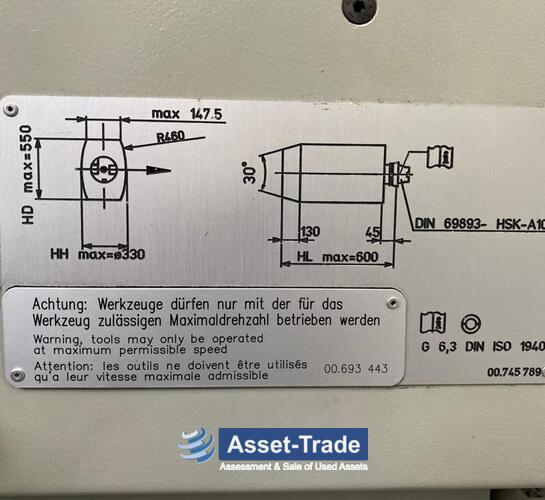

- Spindle speed: 45-6000 rpm

- ICZ: 70 bar 22 l / min

- Tool holder: HSK 100 DIN 69893

- Tool magazine: 320 pieces

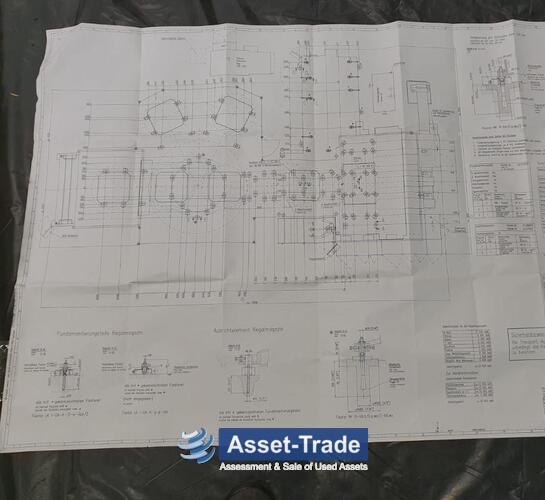

Full machine details see included PDF

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER 4-axis machining centres. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes – even at their limits, seven days a week in 3-shift operations.

Key facts

4-axis machining centres at a glance

|

|