This great EMCO - Compact 5 Mini-Lathe is unfortunately already Sold.

Discover further Metalworking » Lathes machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:2.400 rpm

-

Turning diameter:65 mm

-

Turning lenght:350 mm

-

Tailstock:Yes

Description:

This great EMCO - Compact 5 Mini-Lathe is unfortunately already Sold.

Discover further Metalworking » Lathes machinery, or Contact us for further help.

Used EMCO compact 5 Mini-Lathe

Build 1990

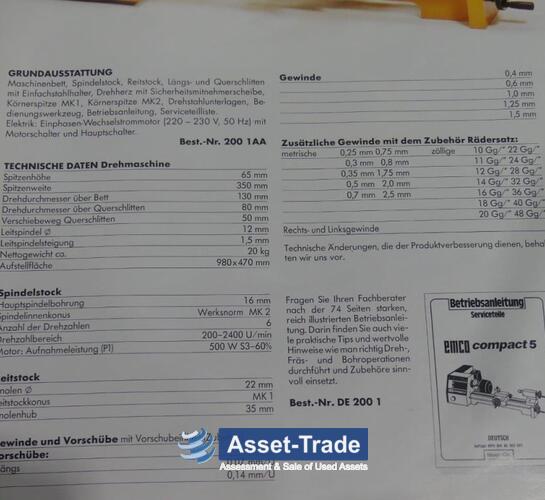

Further DATA:

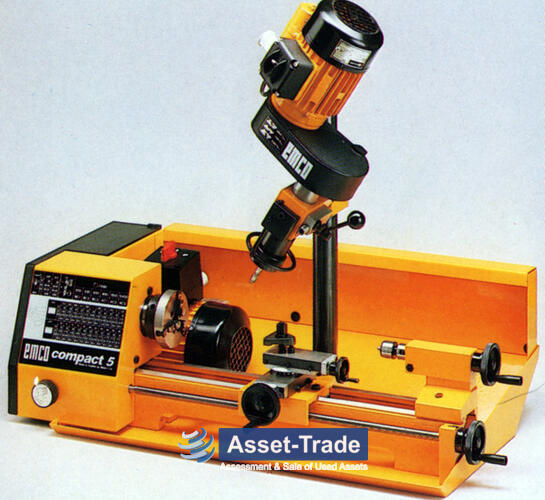

Compact 5 with the milling and drilling head fitted: capacity 2.56" x 13.78" (65 mm x 350 mm) with 6 spindle speeds from 200 to 2400 rpm. Long established and very popular, the Emco Compact 5 in its basic form does requires a number of accessories to turn it into a useful work tool - if you are looking at a used example the most import accessories are a swivelling top slide (often referred to as the "compound" and the automatic carriage-feed mechanism - a 2-speed device that included 6 changewheels and a push/pull engagement knob for the dog clutch. Using the unit gave two rates of fine longitudinal feed (0.07 mm (0.003")/rev and 0.14 mm (0.006")/rev and five metric thread pitches (0.4, 0.6, 1.0, 1.25 and 1.5 mm) - though only four (16, 20, 24 and 32 t.p.i.) on inch machines. To make the screwcutting system complete a further set of 7 seven changewheels were offered that allowed, on metric lathes (with a 1.5 mm leadscrew), the generation 10 metric pitches from 0.25 to 2.5 mm and 14 inch pitches from 10 to 48 t.p.i. On inch models - the leadscrew was 16 t.p.i.) 13 pitches from 10 to 10 to 64 t.p.i. were provided together with 11 metric from 0.25 to 1.75 mm.

Running in deep-groove, sealed-for-life ball bearings the headstock spindle was bored through 16 mm, had a No. Morse taper socket and was equipped with a safe (though slow-to-change) "bolt-on" spindle nose flange. Driven by a 500 Watt motor, six spindle speeds were provided that ranged from 200 to 2400 r.p.m. on a 50-cycle supply and 250 to 2800 on 60-cycle (as used in North America). The speed range is pretty well spot-on for small modelling work, allowing larger casting to be turned as well as small pins.

Able to be set over for the turning of slight tapers, the tailstock carried a 22 mm diameter spindle fitted with a No. 1 Morse taper socket.

The usual wide range of factory-supplied accessories was available including (in addition to those already mentioned) a very useful if rather lightly-built power vertical milling and drilling head, 3 and 4-jaw chucks, dividing attachment, a T-slotted faceplate (also used as a "clamping plate" on the dividing attachment), T-slotted boring table, tailstock chucks and rotating centres, turning, threading and boring tool sets, a 2-way toolpost, quick-set toolpost, fixed and travelling steadies, top slide, splash guard and a collet attachment to take ESX collets from 1.5 to 14 mm.