This great HELLER - MC 200 5-Axis is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Universal Machine Centres machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:10.000 rpm

-

Tool Capacity:55 x

-

X-Axis:800 mm

-

Y-Axis:800mm

-

Z-Axis:1.000 mm

Description:

This great HELLER - MC 200 5-Axis is unfortunately already Sold.

Discover further Metalworking » Machine Centers » Universal Machine Centres machinery, or Contact us for further help.

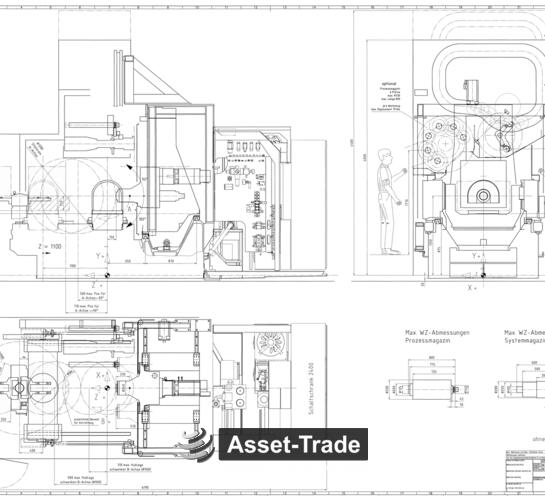

Used Heller MC 200 machining center 5 axes

Control CNC Siemens 840D

Technical specifications

- Travel:

- X-axis 800.0 mm

- Y axis 800.0 mm

- Z axis 1000.0 mm

- Table size 630.0 mm x 500.0 mm

- Workpiece weight 1500.0 kg

- Tool changer 55x

- Spindle cone HSK100

- Max. Spindle speeds 10,000 rpm

- Spindle motor power 37 kW / 490Nm

- Number of pallets 2.0

- IKZ 50 bar

- Dimensions length x width x height 7.0x 3.2x 4.0m

The distinct advantages offered by the machine are:

Robust bed construction giving a high degree of machine rigidity · Well dimensioned motor spindles providing excellent power at the spindle and best milling characteristics · Maintenance-free AC motors for main spindle and feed drives · High fine boring quality due to direct spindle drives · High thermal stability of the unit is achieved by grease-lubricated spindle bearings and a water-cooled motor spindle drive · Shortest positioning times through high rapid traverse rates and fast acceleration values · Low-friction roller bearing guideways, robust ball screw drives together with direct path measurement with absolute linear scales give higher positioning and circular interpolation accuracy · Optimum acceleration of linear axes through good relation of masses and drive design · A wide speed range and internal coolant supply through the spindle give optimum tool utilisation · Controlled tool changers equipped with servo motors provide shortest chip-to-chip times · Short tool access times through clockwise/anticlockwise rotation and high speed of the magazine and direct access of the tool changer to the magazine places · Machine is ready for integration into highly automated HELLER manufacturing system · Efficient chip disposal and compact work area · Enclosed work area provides a clean machine environment. · User-friendly operation of the control promoting efficient workshop practices