This great WEIPERT - HFS 1000 x 500 Surface Grinding Machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines machinery, or Contact us for further help.

Ref. No.:

1150-12111949

Products

Machine Details:

Technical Details:

-

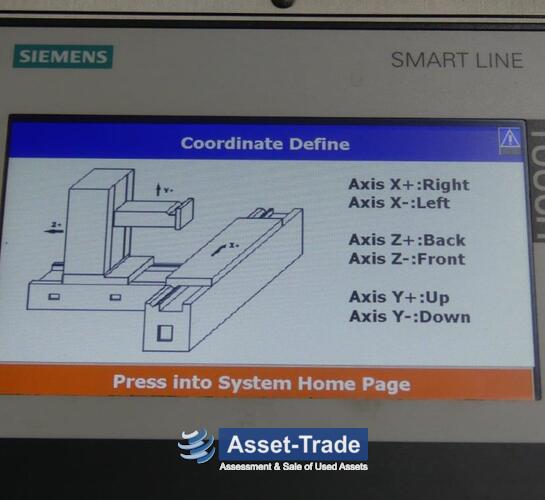

Control:

Description:

This great WEIPERT - HFS 1000 x 500 Surface Grinding Machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines machinery, or Contact us for further help.

Description

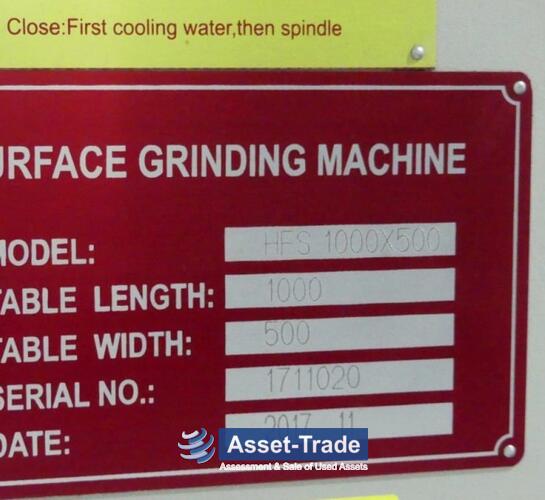

Used Weipert HFS 1000 x 500 Surface Grinding Machine

Technical Data

- Feed depht Y-Axis 0,005 - 0,04 mm

- Travel 1000 x 500mm

- Spindle speed (50 Hz) 1.450 1/min

- Distance spindle nose - Table 590 mm

- Main Drive 7,5 kW

- Travel X-Axis 1140 mm

- Grinding Wheel dimension 355x40x127 mm

- Travel Y-Axis 540mm

- Machine dimension (LxBx H) 4,45x2,2x2,2 m

- Feed speed X-Axis 5 - 25 mm/min

- Weight 5.000 kg

- Automatic feed Z-Axis 0,5 - 12 mm/min

Further information

- The rigid, wide work table moves only on one axis - this design allows for an extra-long table guideway on a very wide machine base, ensuring perfect load distribution at both travel end positions.

- V-guides and boxways are counter-laminated with Turcite B ensuring smooth table movement at any load.

- Column moves in the Z axis on hand-scraped, counter-laminated V-guides and boxways ensuring total elimination of any stick-slip effect.

- The grinding spindle moves only vertically - this design ensures 100% exact grinding wheel feed with maximum angular precision across the entire work area.

- Hydraulically operated linear table movement, infinitely variable, high consistency, and soft reversal of direction the stand-alone hydraulic unit is easy to maintain and mechanically and thermally separated from the main machine frame to ensure the most constant working conditions possible.

- Large grinding spindle, dynamically balanced, completely sealed with permanent lubrication

- Grinding spindles are carefully assembled by experienced professionals in air-conditioned clean rooms using selected precision bearings.

- Once the machine is put into operation, the automatic central lubrication system supplies all guides and preloaded ball screws with the correct amount of oil.

- Optionally, all models can be equipped with a mechanical grinding wheel dresser that can be used at any grinding height and column position - this reduces unnecessary down-times.