How can we help you?

No used machines currently found

We are sorry, but we currently do not carry used machines from How can we help you? .

Please use our search box to find similar products

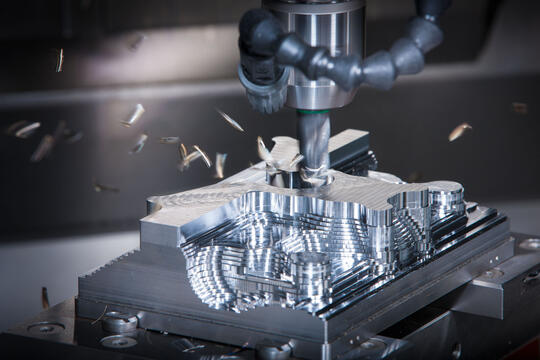

Used AXA UPFZ 40 5-axis portal milling system

Optimal for machining of large ALU and steel assemblies like cross girder, long beam, underframe section

Component measurement within the machining planes as a basis for adapting the NC… Know More

Maschinen Informationen

The Wheel Rim Production line LMF1 is a comprehensive system designed for the manufacturing of large-format steel wheel rims, with a capacity for sizes ranging from 18 to 42 inches. The line integrates core forming, welding, and… Know More

Maschinen Informationen

Used Car Wheel Rim Production Line – Complete, Automated System by Fontijne, Kuka & Georg

Complete retrofit in 2023/2416“ diameter / 6.5” wide Throughput time of 8 seconds (7.5 hour shift / 3-shift) approx. 4,500 units

For… Know More

Used CMZ TD-35Y CNC Lathe: Power, Precision, and Reliability for Complex Machining

State-of-the-art Fanuc CNC Control

Discover the ultimate in turning performance with the CMZ TD-35Y. Designed for demanding production environments,… Know More

Used Keppler manufacturing cell / 3-axis machining center (2005). With Siemens control, integrated handling, HSK63, double fixture, and Kelch tool presetter.

For sale is a complete, automated manufacturing cell built around a 3-… Know More

Used 3-axis CNC machining center Matec 30L for sale. With Heidenhain DNC426CB control, 2000mm X-axis, pendulum mode, and NEW SK40 spindle!

For sale is a robust and versatile 3-axis CNC machining center from the quality German… Know More

Maschinen Informationen

For sale is a complete and robust wheel rim production line (LMF1), specifically designed for manufacturing large and heavy-duty steel rims for trucks, agricultural, and construction vehicles. The line covers the entire production… Know More

For sale is a like-new, highly efficient, and fully integrated compressed air station from the premium manufacturer Kaeser. All core components, from the three screw compressors and the air treatment system to the intelligent… Know More

Maschinen Informationen

Modern Thermal Oxidizers by Dürr / LTB (Year of Manufacture 2019)

For sale are two modern thermal oxidizers from 2019 for the highly efficient purification of solvent-laden process exhaust air (VOCs). These systems from the global… Know More

For sale is a selection of four powerful hydraulic frame presses, ideal for demanding drawing, stamping, and forming operations. The collection includes robust and proven models from traditional German manufacturers Umformtechnik… Know More

For sale is a complete and compact wheel disc production line. This facility consists of a fully integrated Schleicher coil line (decoiler and straightener) and a robust 4,000 kN (approx. 400 t) press from Umformtechnik Erfurt. The… Know More

Maschinen Informationen

For sale is a powerful production line for manufacturing wheel discs directly from coil. The heart of the system is a robust 16 MN (approx. 1600 tons) drawing and stamping press from Schirmer + Plate, fed by a modern Schleicher coil… Know More