This great KLINGELNBERG - Oerlikon L 60 A Lapping Machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines machinery, or Contact us for further help.

Description:

This great KLINGELNBERG - Oerlikon L 60 A Lapping Machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines machinery, or Contact us for further help.

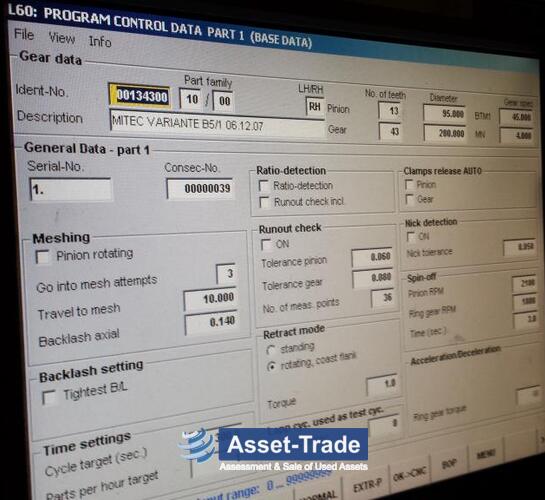

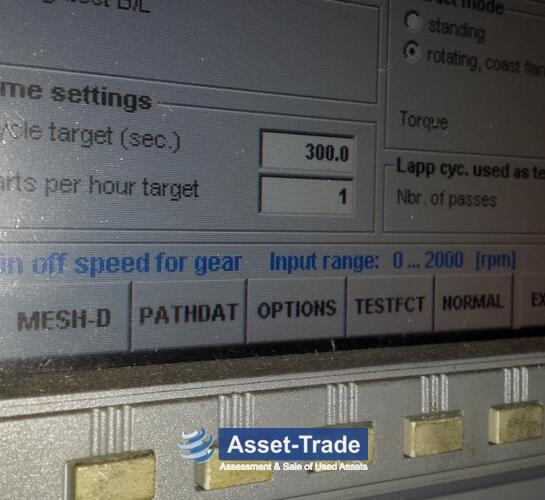

Used KLINGELNBERG Oerlikon L60A for spiral and hypoid bevel gears

- Only 360 hours

- Fanuc control

- Machining diameter: max. 500mm

- Working length:

- Y-axis: 150 - 350mm

- Z-axis: 120 - 340mm

- 2 spindles

- A-Axis for 79° to 101°

- Power: 4.8 kw

- Tool: inner cone No. 39

- Spindle speed

- Gear: 0 - 4000 rpm

- Pinion: 0 - 3000rpm.

The machine has about 360 hours and was set in 2007/08 for production of a few prototypes, never run in serial operation and is thus almost in new condition.

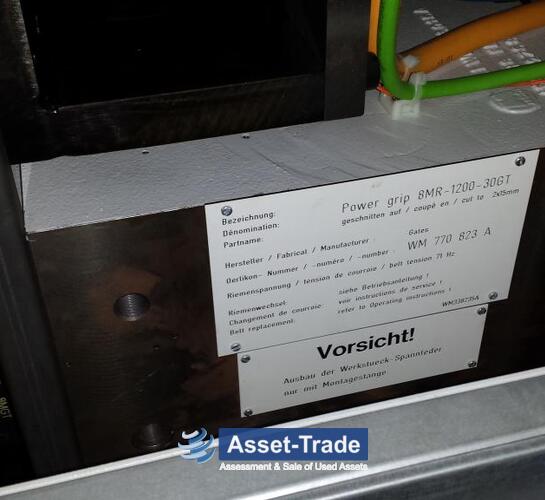

Using the proven horizontal spindle concept of it's predecessors, axis have cleverly been rearranged using the innovative cross-sledge design providing optimal functionality and process capability, without compromises regard ing floor space requirement and accessibility. Special attention was given to housekeeping requirements to ensure a clean machine environment without compromising on

full accessibility.

- Fully integroted auxiliary units

- No hydraulic unit

- Spillage free lapping compound change

- High rpm spin-off cycle

The mochine has been designed in such a way, that all operational tasks; loading, unloading and exchange of lapping compound can be performed from the front face of the machine, giving full freedom to factory layouts.

Special attention was given while designing the layout of the machine to ensure that not only the

actual floor space was taken into consideration but that the passive floor space requirements were minimized as well therefore allowing a closer arrangement of machines, minimizing both nonproductive areas and operating distances.