This great KARL ROLL - RUT-090-045-050-04 Ultrasonic washing machine is unfortunately already Sold.

Discover further Metalworking » Other Machines » Surface Treatment machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

Description:

This great KARL ROLL - RUT-090-045-050-04 Ultrasonic washing machine is unfortunately already Sold.

Discover further Metalworking » Other Machines » Surface Treatment machinery, or Contact us for further help.

Used Karl Roll RUT ultrasonic washing machine with drying unit

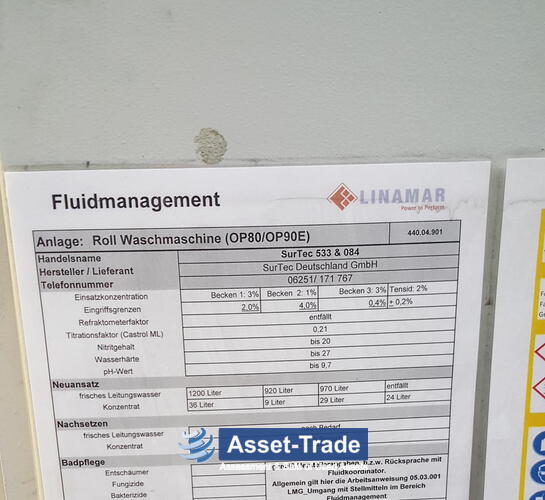

The automatic cleaning system is used exclusively for the cleaning and degreasing of metal parts by means of aqueous media

Technical data for the fully encapsulated cleaning system for ultra-fine cleaning:

- CNC Control Siemens S7

- Part size 900x450x500 max 250 kg

- Depending on the program a maximum of 13 batches / hour

- Stainless steel basket

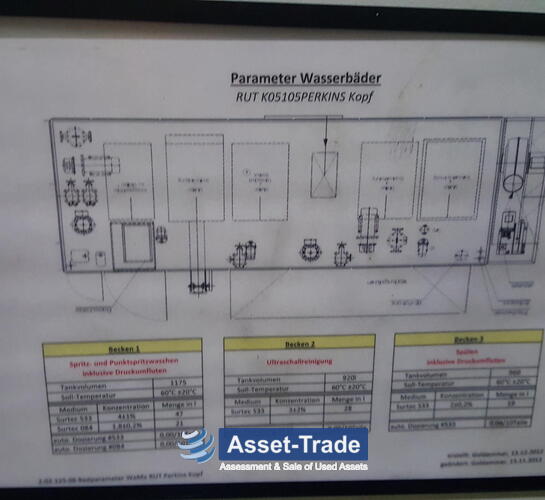

- Container contents:

- Sampling container for station 1 approx. 880 liters

- Oil separator 1 approx. 300 liters

- Station 2 approx. 920 liters

- Station 3 approx. 960 liters

- Volume of the basin is approx. 3470 liters

- heating

- Sampling tank for station 1 36 kW (electric)

- Station 2 27 kW (electric)

- Station 3 27 kW (electric)

- Compressed air connection DN 15

- Current type 400 Volt, 50 Heart, 185 kW, 318 A

- Space requirement WxLxH 7500 x 10500 x 4250 mm

The cleaning system consists of:

- Frame with integrated floor pan and cover plates

- Horizontal driving device

- Vertical lifting device

- Goods transport device

- Drum means

- Cleaning and rinsing containers, vacuum drying,

- Heating device for the cleaning and rinsing containers,

- ultrasonic device

- filtration device

- oil separator

- Pumping and discharging device

- After dosing device

- Anlagenabsaugung

- Electrical control cabinet

- Supply and discharge roller track for this purpose is provided with a return roller track

- Cooling tunnel on unloading line

MULTICHAMBER IMMERSION FACILITIES

These facilities always find application when high throughputs, large batch weights, complicated part geometries and complex multilevel processes are involved. The configuration as well as the accessory range is tailored in each case to customer requirements.

A tried-and-tested transfer system with removable basket holders means that the fully automatic multichamber immersion facility allows cost-effective retrofitting of additional basket holders that flexibly increase the throughput performance. Alternatively, additional basket holders can lengthen process times in the individual stations whilst maintaining the same throughput capacity and thus fulfil the demands for higher cleanliness.

Multichamber immersion facilities also offer the largest possible degree of flexibility for goods movement, cleaning agents selection and accessories. Simultaneous swivel/turn and lifting movements can be easily integrated into this facility concept. Machine technology permits the use of efficient immersion tensides or aggressive media in plastic tanks and the system offers the lowest drag rates for complex demands of cleaning agents mixing and rinsing quality.